- home

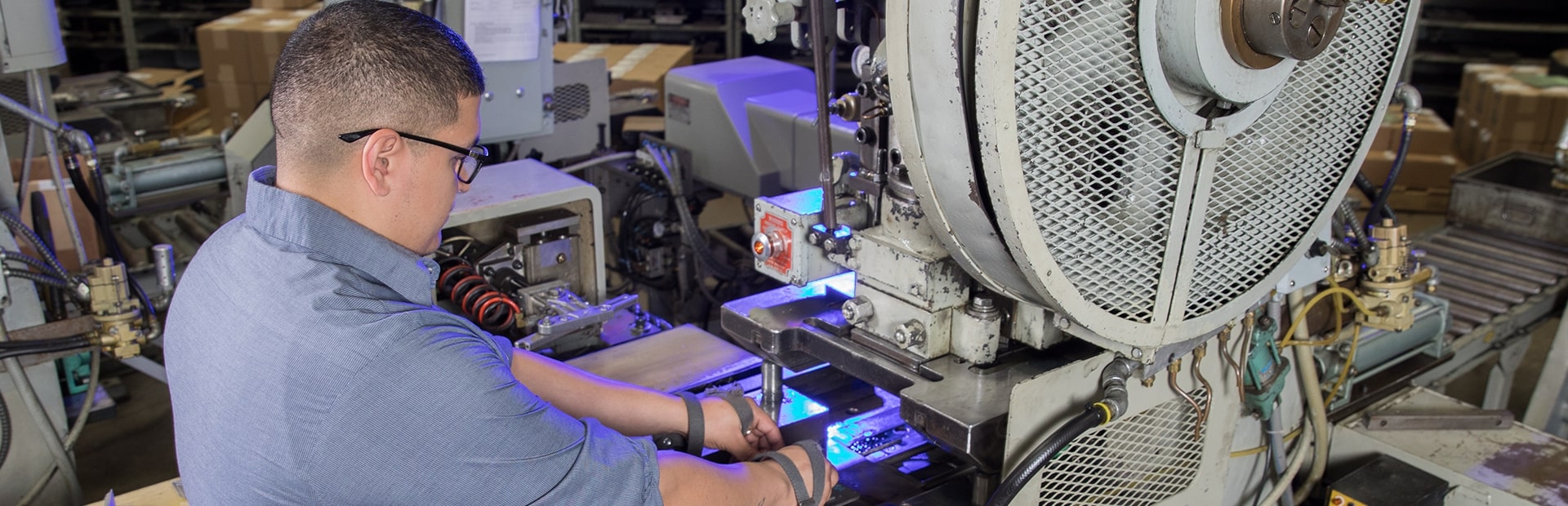

- metal stamping

- in-house tooling

- value added services

- Design and Engineering

- popular materials

- stainless steel

- aluminum

- cold rolled steel

- hot rolled steel

- pre-galvanized steel

- annealed steel

- brass

- copper

- plastic

- key industries

- lighting

- furniture

- mounting systems

- industrial automation

Winco Stamping Inc.

W156 N9277 Tipp Street, Menomonee Falls, WI 53051

Phone:

E-mail: [email protected]