At Winco Metal Stamping we’re proud to provide quality metal and plastic parts for a number of successful clients in the furniture industry. Our short-run and medium-run times lead the industry in efficiency. We’re ready to help your business reach the next level. We’ve been helping furniture manufacturers like you for over 60 years.

“Their ability to turn product around. When you need them to step up they go the extra effort when you need it.” – Furniture Industry Client

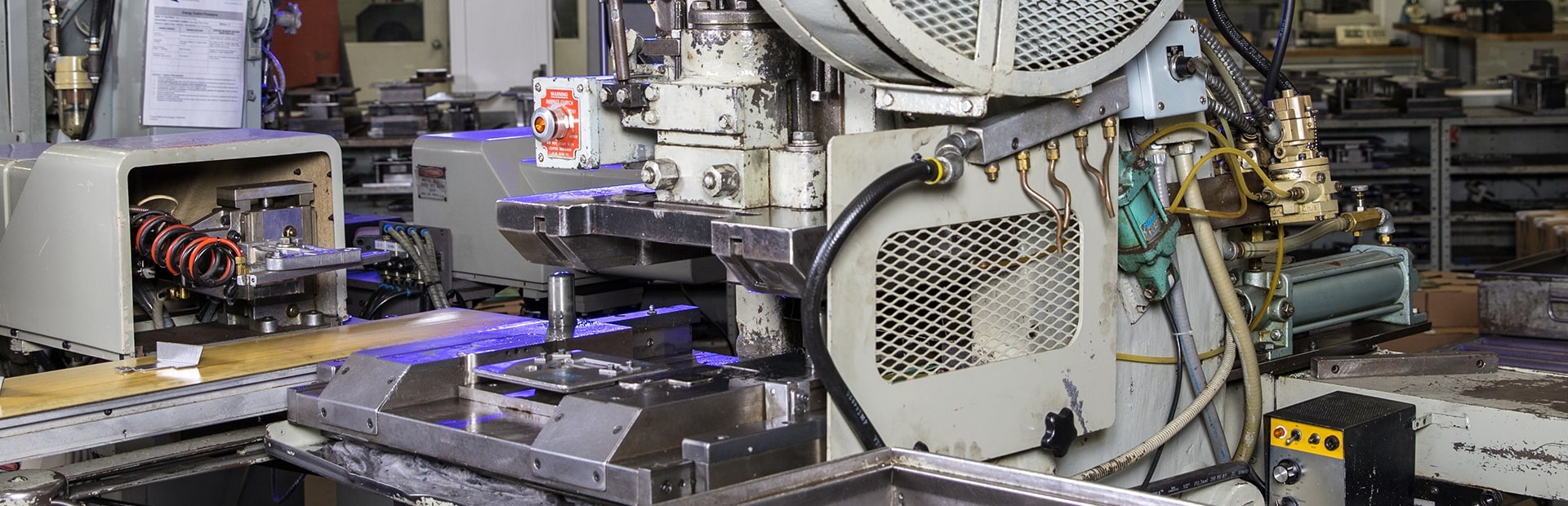

Winco Stamping has the industry knowledge and experience to equip your company with high quality stamped metal furniture parts. Our proven in-house tooling process will produce the components you need to your exact specifications, on time, and on budget.

We provide metal furniture parts to manufacturers for:

- Decorative furniture

- Office furniture

- Industrial furniture

- and more!

Furniture Metal Stamps

Metal forms from Winco Stamping have continuous edges, no nibble marks, die controlled dimensions and all the burrs are on the same side of the part. We have experience stamping furniture parts from cold rolled steel, aluminum, stainless steel, copper and more!

Tooling for Furniture

Winco provides a great advantage over other manufacturing processes in the furniture industry. With standardization of in-house equipment, we’re able to react quickly to any design changes. And thanks to our tooling guarantee, you’ll get your samples on time - or your tooling is free!

Value Added Services

We don't just stop at stamping. Our secondary services for furniture parts include PEM insertion, riveting, machining, and welding. We’re here to be your partner and support in your production goals by providing the best assembly every single time.

Our experienced team and industry leading equipment allows us to provide metal stampings with blanked dimensions +/-.005″ on shear side of the part and formed dimensions +/-.010 inside a bend. We specialize in product start-ups, legacy products and low to medium volume product lines.

You can trust that we’ll provide the highest quality furniture parts available because our management system is ISO 9001:2015 certified.

Contact us now for a free cost quote on your next project!